The Function of Fasteners and Machining in High-Quality Item Layout

The Function of Fasteners and Machining in High-Quality Item Layout

Blog Article

Introducing the Ins And Outs of Bolts and Machining Processes for Optimum Efficiency

In the realm of design and manufacturing, the selection of bolts and the complexities of machining procedures play a crucial function in identifying the supreme efficiency and toughness of a product. From the apparently simple job of selecting the right kind of fastener to the complex accuracy machining techniques used, every step in this procedure demands careful attention to information. As we start this exploration right into the world of bolts and machining, we will discover the refined yet vital variables that can substantially influence the effectiveness and top quality of the end product, losing light on the usually forgotten facets that can make all the distinction in achieving ideal efficiency.

Value of Appropriate Fastener Selection

Picking the ideal bolts is important in guaranteeing the structural honesty and durability of any mechanical setting up. Bolts play an essential role in holding components with each other safely, with the right selection contributing considerably to the total efficiency and reliability of the setting up. When selecting bolts, variables such as material compatibility, environmental problems, load-bearing capacity, and convenience of setup should be meticulously thought about to guarantee optimum performance.

Inappropriate fastener selection can cause a variety of concerns, including helping to loosen, corrosion, and also structural failure. Making use of fasteners that are not matched to the certain requirements of the setting up can endanger its performance and posture security threats. Developers and engineers should diligently assess the application requires and pick fasteners that meet or surpass the essential standards and specifications.

Moreover, the proper fastener choice procedure entails evaluating the joint style, prepared for lots, vibration levels, and prospective thermal growth or contraction to make certain that the picked fasteners can stand up to the operating problems properly. By focusing on correct bolt option, manufacturers can enhance the quality, toughness, and efficiency of their mechanical settings up.

Types and Qualities of Fasteners

A necessary element of mechanical assemblies exists in recognizing the diverse kinds and one-of-a-kind attributes of fasteners made use of in numerous commercial applications. Fasteners are crucial parts that hold structures with each other, making sure stability and capability.

Screws are threaded bolts that are typically made use of to sign up with two or even more elements together. Bolts resemble screws however are commonly used with a nut to develop a safe joint. Nuts are internally threaded fasteners that mate with bolts to hold parts with each other. Washers are slim plates that distribute the tons of a fastener, stopping damage to the product being fastened. Rivets are long-term fasteners that are hammered or pressed right into location. Pins are made use of for positioning or to safeguard components momentarily.

Recognizing the features of each kind of bolt is essential for picking the appropriate one for a certain application, making certain optimum performance and reliability of the mechanical assembly. Fasteners and Machining.

Accuracy Machining Strategies for Performance

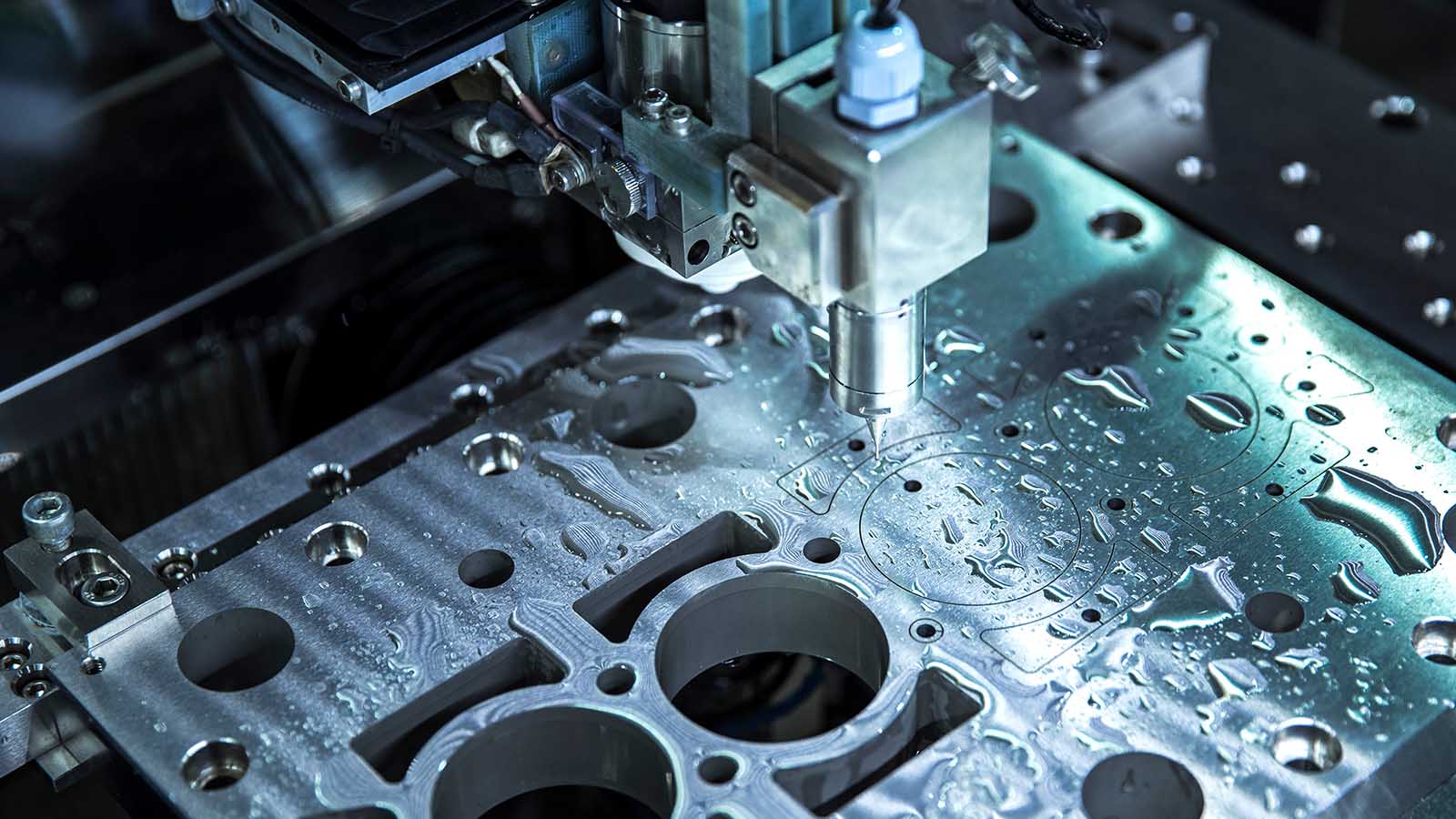

The complex style demands of various bolts demand utilizing precision machining techniques for optimum performance in making processes. Precision machining is crucial in making certain that bolts satisfy the exact requirements required for their designated application. One of the key methods utilized in accuracy machining is Computer Numerical Control (CNC) machining, which allows high levels of precision and repeatability in the production of fasteners. CNC makers are capable of carrying out complicated cuts and shaping operations with marginal human treatment, causing increased performance and consistency in the production procedure.

By making use of accuracy machining techniques, makers can improve the top quality of bolts, lower product waste, and boost total manufacturing performance. The usage of innovative machining procedures aids guarantee that fasteners satisfy market requirements and client expectations for performance and reliability.

Elements Affecting Machining Process Efficiency

Different variables play a substantial duty in determining the performance of machining procedures in the production of bolts. Maximizing these criteria based on the specific requirements of the fastener being produced is key to achieving economical and exact machining.

Maker rigidness and security likewise play a critical duty in establishing machining procedure efficiency. A steady device with minimal vibrations can boost precision and stop tool wear, resulting in better overall performance. The skill and experience of the equipment driver can not be ignored. A well-informed operator can make real-time changes, troubleshoot problems successfully, and make certain that the machining process runs smoothly, eventually influencing the final quality of the bolt.

Quality Assurance Steps in Manufacturing

Aspects influencing machining process performance, such as cutting tool selection and machine security, straight influence the execution of top quality control procedures in production. Quality control steps are vital Full Report in guaranteeing that items fulfill helpful resources the needed standards and specifications. In the production procedure, different techniques are employed to maintain high quality requirements. Evaluation and testing play a critical duty in determining any type of deviations from the wanted result. Routine maintenance of machining tools is likewise vital to promote high quality control. Calibration of makers and tools is needed to guarantee accurate and specific production processes. In addition, executing standard operating treatments and protocols can assist in maintaining uniformity and quality throughout the assembly line. Quality assurance determines not just focus on the end product yet likewise on every phase of the manufacturing procedure to avoid issues and errors. By sticking to rigorous quality assurance actions, makers can boost customer satisfaction, develop a reputation for dependability, and inevitably achieve ideal efficiency in their machining processes.

Final Thought

In conclusion, choosing the ideal bolts and using accuracy machining methods are crucial for optimum performance in manufacturing procedures. Recognizing the kinds and features of bolts, in addition to variables affecting machining process performance, can lead to enhanced effectiveness and quality assurance procedures. By paying interest to these ins and outs, makers can accomplish higher levels of efficiency and integrity in their items.

In the world of engineering and production, the choice of fasteners and the complexities of machining processes play a crucial function in figuring out the ultimate performance and toughness of a product (Fasteners and Machining). One of the key methods utilized in precision machining is Computer system Numerical Control (CNC) machining, which allows high levels of precision and repeatability in the production of fasteners. The usage of sophisticated machining processes aids make sure that fasteners fulfill market criteria and client expectations for find here efficiency and dependability

In conclusion, choosing the best bolts and using accuracy machining methods are important for optimum performance in making processes. Recognizing the types and qualities of bolts, along with aspects affecting machining process efficiency, can lead to improved performance and quality control actions.

Report this page